XR-Based Training for Safe Operation of Hydraulic Press

In industrial settings, proper training is essential to ensure the safety and efficiency of workers operating heavy machinery. However, traditional training methods can be limited by logistical challenges, risks, and costs. PRESENCE provides a next-generation XR-based training solution that allows employees to gain hands-on experience in a fully virtual, safe, and controlled environment.

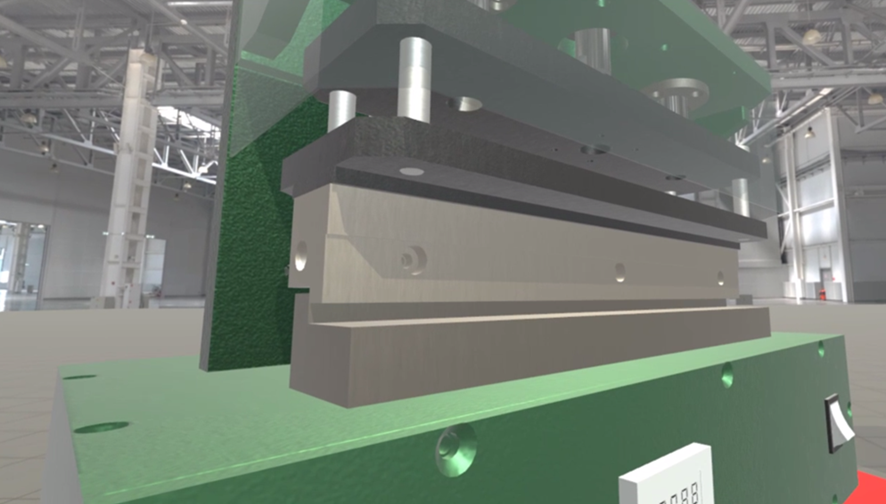

In this use case, three trainees: Alex, Sarah, and Lisa are preparing to operate a hydraulic press in a steel factory. Under the supervision of Tom, a factory supervisor holoported into the session, the trainees put on VR headsets to enter a digital twin of the manufacturing floor. The training room accurately simulates the factory environment, including a fully interactive hydraulic press.

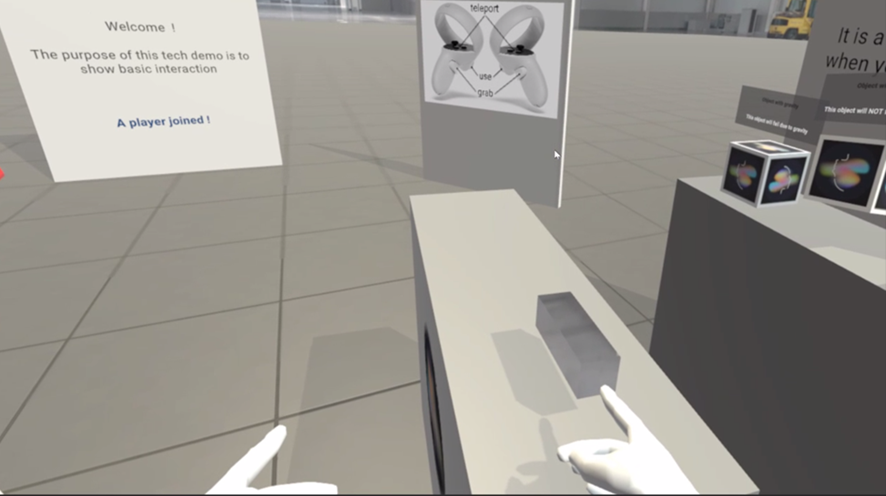

The trainees are guided by an intelligent virtual assistant (IVA) that demonstrates proper and improper machine operations, reinforcing critical safety protocols.

During the training session, the IVA walks the trainees through three core machine operations:

1. Using the hydraulic clamp: Trainees learn to correctly place a heavy steel sheet inside the press and remove excess scrap after processing. To simulate real-world risks, Alex, equipped with haptic gloves, feels a strong vibration if he attempts to touch the steel before the cooling period ends.

2. Operating the safety door: Trainees practice opening, closing, and locking the machine’s safety door, experiencing force feedback through their controllers to simulate realistic interactions.

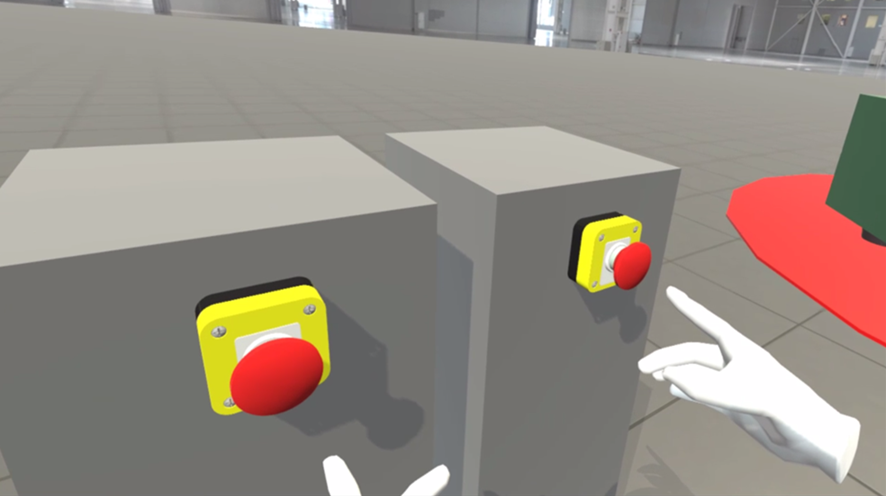

3. Activating the machine: The trainees press two buttons simultaneously to start the blanking action. Alex, using haptic gloves, experiences force feedback when pressing the buttons, while the others feel slight vibrations through their controllers.

Throughout the training, Tom observes the trainees’ actions and provides feedback on their performance, ensuring they understand the correct procedures before attempting real-world operation. After completing the tasks, Tom evaluates their competency and concludes the training. The immersive nature of the training not only enhances skill acquisition but also significantly reduces risks associated with learning to operate industrial machinery.

Technology Highlights:

- Holoportation: Tom supervises the trainees remotely, providing real-time guidance.

- Haptics: Alex’s gloves simulate the sensation of heat, weight, and force feedback, increasing training realism.

- IVA Assistance: The intelligent virtual assistant demonstrates correct and incorrect procedures, reinforcing safety practices.